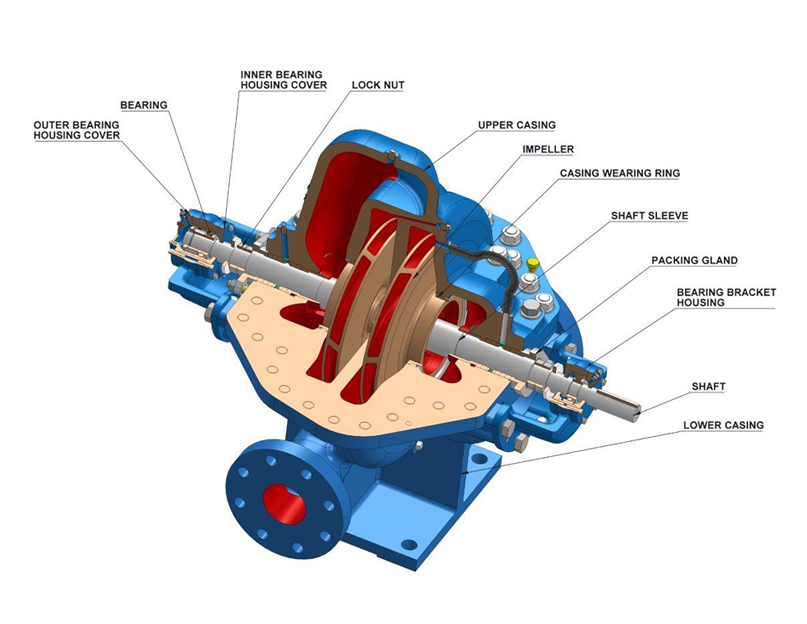

Pump Impeller

This is the fundamental pivoting portions of the pump that gives the diffusive increasing speed to the liquid. Impellers might be grouped from various perspectives. For instance: According to the bearing of fluid stream concerning the hub of rotation of the shaft. These pumps can be purchased from Desalination pump manufacturers.

Types of Pump Impellers

- Axial flow

- Radial flow

- Mixed flow

According to suction type

- Single suction

- Double suction

According to the mechanical construction of vanes

- Closed vane type

- Open vane type

- Semi-open type.

An impeller in a pump is the part that the engine turns and that really accomplishes crafted by moving the water. Because of its structure when the impeller turns it makes a vacuum that pulls the water or fluid in an opening on the facade of the impeller (suction side) and tosses it to the outside through the release where it is then directed to the yield of the pump. There are many kinds of pups and impellers and these can be bought from Horizontal Pumps Manufacturer India.

The impeller is the fan-like circle that really drives the fluid in the pump chamber.

Impeller makes the stream to gain speed and speed in a diffusive pump. The reason for the pump is to build the weight of the water.

A diffusive pump has an admission that permits fluid to enter the pump. Within the admission, mechanical assembly is a circle with balances which is joined to an engine. The propeller turns at a fast and enables to pump more water. These impellers make the function of a pump smooth and these pumps can be purchased from Vertical turbine Pumps Manufacturers

Impellers of pumps are ordered dependent on the number of focuses that the fluid can enter the impeller and furthermore on the measure of webbing between the impeller cutting edges.

Impellers can be either single suction or twofold suction. In a solitary suction impeller, fluid enters the focal point of the edges from just a single course. In a twofold suction impeller, fluid enters the focal point of the impeller edges from the two sides simultaneously. End Suction Pumps manufacturers India manufactures all kinds of pumps and impellers for industrial needs.

Impellers can be open, semi-open, or encased. The open impeller comprises just of edges connected to a center point. The semi-open impeller is developed with a round plate joined to the other side of the cutting edges. The encased impeller has roundabout plates appended to the two sides of the sharp edges.

The impeller once in a while contains adjusting gaps that interface the space around the center to the suction side of the impeller. The adjusting openings have an absolute cross-sectional zone that is extensively more prominent than the cross-sectional zone of the annular space between the wearing ring and the center. The outcome is suction pressure on the two sides of the impeller center, which keeps up a water-powered equalization of hub push.

Impellers are chosen based on the pump configuration requires and the use of the pump.

As a rule, the higher the quantity of vanes in the impeller, the more noteworthy is the effectiveness of the impeller. The exhibition bend of a pump is likewise influenced by the number of vanes.

The brake strength shifts as a 3D square of the impeller width.