The reliable and tried-and-true vertical turbine pump can be found anywhere on Earth where there is an industrial environment. This pump design allows for ongoing operational advancements in critical global industries such as mining, oil and gas, petrochemical, chemical, electricity, and desalination. People have seen the advent of vertical pumps more than a century ago. They can resist harsh uses and have a long service history.

What You Should Know About the Scalability of a Vertical Pump

It is possible to prolong a vertical pump to the point where it enters underground in order to generate a positive suction head. One significant benefit is the design’s flexibility, which allows for necessary adjustment and, essentially, accurate sizing through stacking stages or impellers. This feature enables phasing and progressive modifications, which ultimately results in lower operating costs. This is made possible by the pumps’ flexibility to adapt to various business needs, making customized installations possible.

Measurements

Unlike their more common horizontal pump counterparts, vertical pumps are much more space-efficient and have a much smaller footprint. When there is a shortage of room, this is a crucial factor to take into account. The foundation materials of the vertical pump might be improved, which would result in reduced wear and tear, less plant downtime, and an extended lifespan for the pump as a whole.

Efficiency

Since many of them are unable to accomplish it on their own, priming is another obstacle that verticals can avoid. This implies that the vertical pump operator can turn on the pump without first deflating, vacuuming, and filling it with liquid. However, a vertical pump just needs to reach a particular level for the first stage impeller to revolve in order to begin pumping. It is not necessary for the pump to be completely full.

Hydraulics, safety, and mechanical tasks

In terms of mechanics, hydraulics, and safety, horizontal and vertical turbine Pumps India typically differ significantly from one another. Constrained areas and dangerous circumstances are prevalent in many energy applications, which might occasionally increase their total significance.

Verticals are distinguished from other types of pumps by their submerged pump parts and steeper head-flow curves.

The engine of vertical pumps is located on top of the apparatus, which is another characteristic that distinguishes them. Unlike a horizontal pump, which is submerged, this raised pump provides both safety and visibility. Raise the pump motor high enough above the ground to mitigate damage in locations that are prone to flooding.

Many Justifications

A vertical pump would be more suitable in these circumstances.

Dimension requirements and spatial constraints

A horizontal could make your arrangement bulkier and heavier. A horizontal pump may not always be able to satisfy the strict weight and footprint criteria. This is as a result of the pump’s elevated location above ground and horizontal footprint. Furthermore, horizontal pumps are unable to handle applications that call for low flow and high pressure. Vertical pumps can frequently satisfy the demand for smaller, more compact pump designs. These designs maximize the amount of floor space and provide simple replacement of the pump’s components.

When using a vertical pump, the entire system’s hydraulics can be adjusted without having to move the nozzle. Pump operators can occasionally replace horizontal pumps, but the process normally involves drilling bolts into the baseplate and modifying the nozzle to fit the pipe placement that is currently in place. Though it rarely does, this could occur.

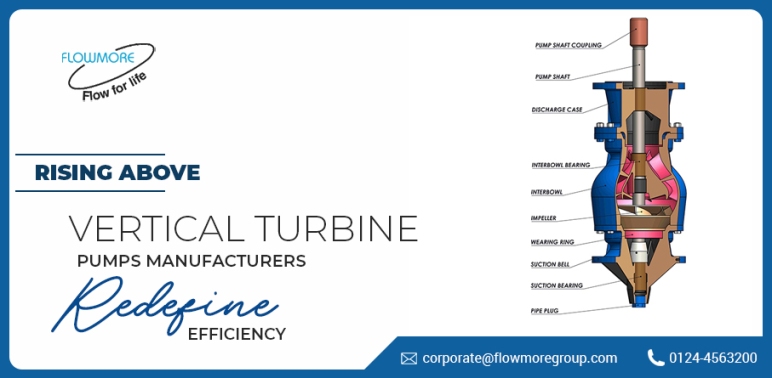

The vertical pump’s lower section, known as the bowl assembly or pumping element, is replaceable. This won’t change where the nozzles are positioned. Furthermore, it is essential that you properly adjust the piping to the appropriate new location or height using the new piping bolts in the event that the pump needs to be moved. The pump’s casing surrounds the pump when it is positioned horizontally.

Also Read:- Elevating Efficiency: Exploring Vertical Turbine Pumps Manufactured in India

In summary

A vertical pump is often better than a horizontal one in energy-related applications since it results in reduced downtime and better site-specific preventative maintenance programs. This could lead to more profitable, dependable, and efficient operations. Finding out about the features and capabilities of each pump design choice at Vertical turbine Pumps Manufacturers that is offered is one method to increase uptime. This is as a result of less system vibration and less stress on the internal parts of the pump. Pump operators are better able to evaluate all of their alternatives and make decisions that support their operations and increase their bottom line when they have a clearer understanding of the whole picture.