1. Appearance

The Vertical Pump is upstanding while the horizontal pump is prostrate.

2. Association structure

Vertical pumps superimpose associate from base to top. The horizontal pumps organize longitudinally on the base. The vertical water pumps are by and large called pipeline pumps, for example, vertical radial pumps. The engine and the pump body are associated at the sub-mouth. Horizontal pumps are associated by coupling and an engine. It needs to address consistently.

3. Space

Vertical turbine Pump possesses a little zone, and horizontal pump involves an enormous region. The vertical pump bunch possesses a more modest region than a horizontal pump. What’s more, it is superfluous to establish a framework, yet the horizontal pump is important on the grounds that has a base.

4. Upkeep

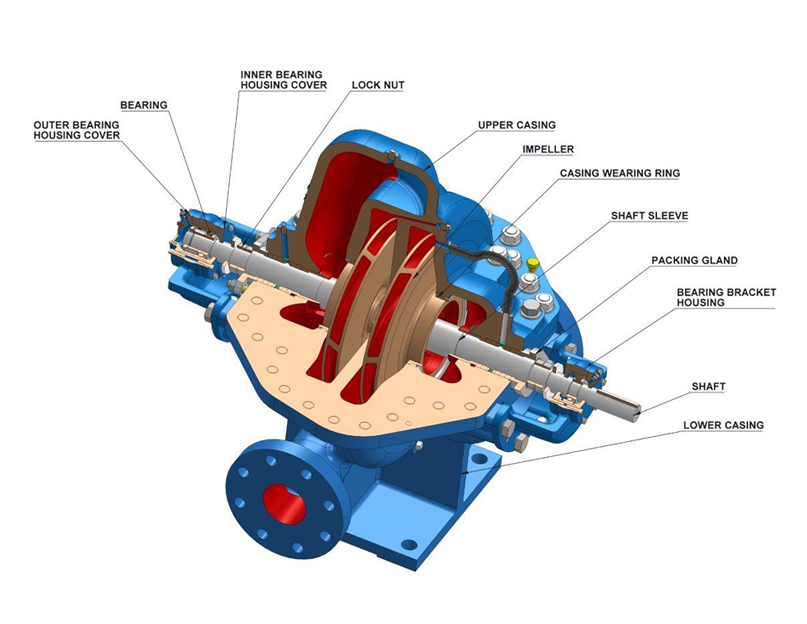

It is hard to support a vertical outward pump. For instance, support of the impeller needs to eliminate all the upper to outside. The horizontal pump is moderately simple. As the IS pump as long as the imported line can be eliminated for impeller support.

5. Establishment

The vertical pump is necessarily associated and simple to introduce. While the horizontal pump requires accuracy change after establishment.

Monetarily, horizontal pumps fabricated by Horizontal Pumps Manufacturer India have a bigger number of points of interest than vertical pumps.

Advantages and disadvantages of vertical pump

Walker vertical pump is another sort of fluid vehicle hardware. it has the benefits of straightforward structure, protected and dependable work, simple support, pressure security, and so on The fly in the salve is moderately touchy to changes in fluid consistency. What are the points of interest and impediments of the Vertical Centrifugal pump? The accompanying will detail it.

Advantage

1. The stream rate is ceaseless and even, the work is steady and simple to change.

2. The pump wear parts are less and simple to oversee and keep up.

3, High speed can be straightforwardly associated with engine or steam turbine. Basic and conservative structure. The size and weight are more modest than a similar stream response pump. It’s low in expense.

Disadvantage

1. The presentation of the pump to the fluid consistency change is more touchy. Each turn of the screw, the depression of the fluid to propel a pitch. With the persistent turn of the screw, the fluid winding route from a fixed hole strain to another fixed pit. At long last, crush out the pump body.

2. Vertical turbine Pumps India is a solitary screw transport pump. Its fundamental working parts are an offbeat screw a lot bramble which the internal surface of the twofold line twisting surface.

3. The force not very enormous- It is truly appropriate for modern and metropolitan seepage. It likewise has extraordinary favourable circumstances during the time spent pressurized water supply in tall structures. We as whole expertise significant the present modern and metropolitan waste for human work and life. Vertical divergent pumps fabricated by Vertical turbine Pumps Manufacturers are assuming a significant job in these regions.

Advantages and disadvantages of horizontal pump

The horizontal pump made by Horizontal Pumps Manufacturer is planned by the rule of radial power. Rapid turning impeller sharp edges drive water revolution. What’s more, toss out the water which accomplishes the reason for transmission. There are numerous sorts of pumps. The gap into common and modern pumps from the utilization. Arrange water pumps, pollutant pumps, erosion safe pumps from the vehicle medium.

Also Read:- What is the application for automatic drainage water pumps?

Advantage

1. Smooth activity. The total concentricity of the pump shaft and impeller brilliant static and dynamic equilibrium to guarantee smooth activity, no vibration.

2. Watertight. Various Materials of solidified carbide seal that ensure the transmission of various media have no spillage.

3. Low clamour. Two low clamour bearing help the pump. Smooth activity, notwithstanding the engine faint sound, essential no commotion.

4. Low disappointment rate. The structure is basic and sensible. The key part receives worldwide top-notch quality coordinating. The entire machine has no disappointment in working time significantly expanded.

5. Simple support. Simple to supplant the seal and bearing.

6, Less space: Exports to one side, right, up to three bearings. At that point the establishment of pipeline design, saving space.

Disadvantage

Primary disservices: Because the axle position of the horizontal diffusive pump is horizontal. When introduced, it occupies more room than the vertical diffusive pump. On account of the restriction of attractions tallness, the establishment position of the water pump is low that simple to be clammy and overflowed. It will influence safe activity.