End suction pumps are a popular type of centrifugal pump used for moving liquids from one area to another. The pump’s design has the input and output connectors on the same side of the housing. Its design permits vertical or horizontal installation of the pump, depending on the amount of pipework that needs to be constructed and maintained.

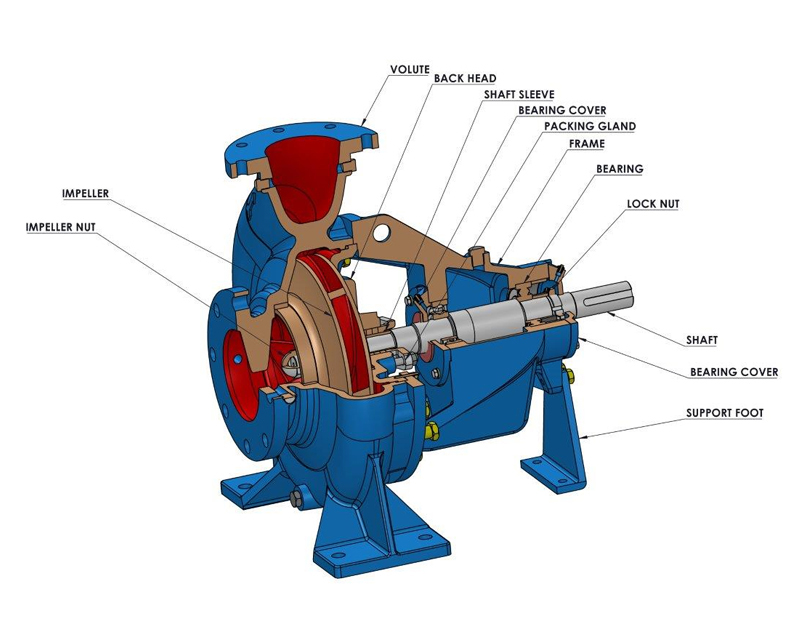

The End Suction Pump converts mechanical energy into hydraulic energy by use of a rapidly spinning rotor. The Flowmore Pumps can then be turned on. As the impeller turns, it generates centrifugal force, which pushes liquids toward the impeller’s periphery. Consequently, a region of low pressure forms in the center of the impeller. In this low-pressure zone, liquid is forced out of the outlet and sucked in through the intake.

End suction pumps are versatile and have been around for a long time

Improved and more reliable versions are used in many different industries, including irrigation and agriculture, heating, ventilation, and refrigeration systems, industrial operations, fire safety, and water distribution and supply. Hot tubs and swimming pools are only two of the many domestic uses for these versatile materials.

Some common uses for end suction pumps are as follows:

Flowmore Pumps are very adaptable and find application in numerous industries that require the efficient and secure conveyance of liquids.

The following are examples of typical uses for end suction pumps:

Water Distribution and Supply:

Its primary function is to transport water from one location to another, making it an integral aspect of water supply and distribution networks. Their primary function is to transfer water from natural sources such lakes, rivers, and wells to either final users or treatment plants. End Suction Pumps also play an important function in water distribution networks by continuously controlling the flow rate and pressure of water.

When used in tandem with refrigeration, HVAC systems; Heating, ventilation, and air conditioning (HVAC) and refrigeration (RF) systems often circulate water and other fluids. Transferring heat or coolants from one system to another is the main focus of heating, ventilation, and air conditioning (HVAC) and refrigeration systems.

An essential part of any fire suppression system are end suction pumps

The use of these Flowmore Pumps aids in the removal of debris from compounds that could be dangerous. The fire suppression system is fed water by a water source and consists of sprinklers, hydrants, and standpipes. The systems that are utilized are these. In order to provide the necessary amount of water for fire-fighting operations, the end suction pumps may be operated at high pressures and flow rates.

For the transport of liquids in many industrial processes, Flowmore end suction pumps are indispensable. Some examples of such liquids are wastewater, chemicals, and petroleum by products. The chemical industry also makes use of them, as they transfer chemicals from storage tanks to other industrial processes. The petroleum sector also makes use of them for transporting crude oil, refined products, and other fluids derived from petroleum.

For fluid handling applications, Flowmore End-suction Pumps India are a great choice due to their many practical properties. Affordable, easily maintained, adaptable in design, and suitable with a wide range of materials and fluids are the characteristics that define reliable and effective pumping solutions. In every fluid transfer application, including water treatment, HVAC systems, and more, end suction centrifugal pumps may deliver dependable performance while reducing energy consumption and costs over time.